Process Control

ProBlue Flex Adhesive Tracking System (ATS) is melt-on-demand technology that provides a way to track and measure adhesive usage in real time, optimizing your packaging line.

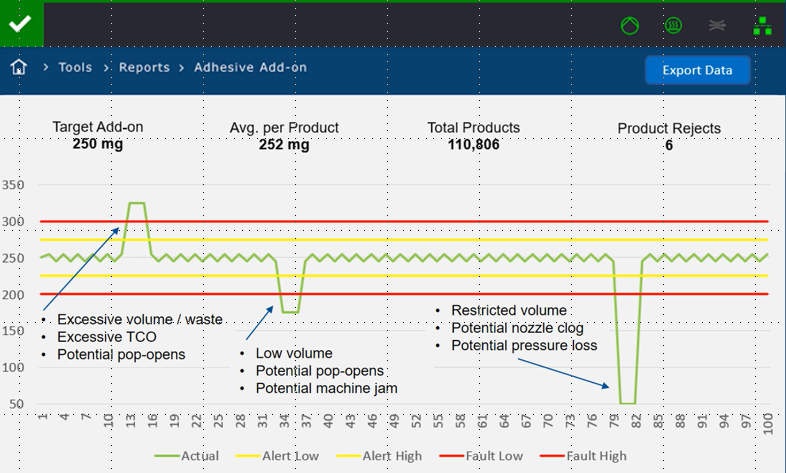

The system combines all the benefits of auto-filling and tankless melting with the cost-saving abilities to minimize adhesive consumption. If the adhesive volume goes outside the settable limits, the system can be configured to send a signal based on custom specifications. The line stops and the light tower illuminates, preventing wasted product and potential pop-opens.

An optional communications card allows the melter to integrate into the parent machine and connect to PLC, giving the users possibility of remote control.

Another part of the Process Control System is the EcoBead Inspect Pattern Generator that lets dispense short, intermittent bead patterns and verify the placement of adhesive on a surface.

Right amount, right place… always